Powering Innovation

Presented by the MIT Department of Facilities

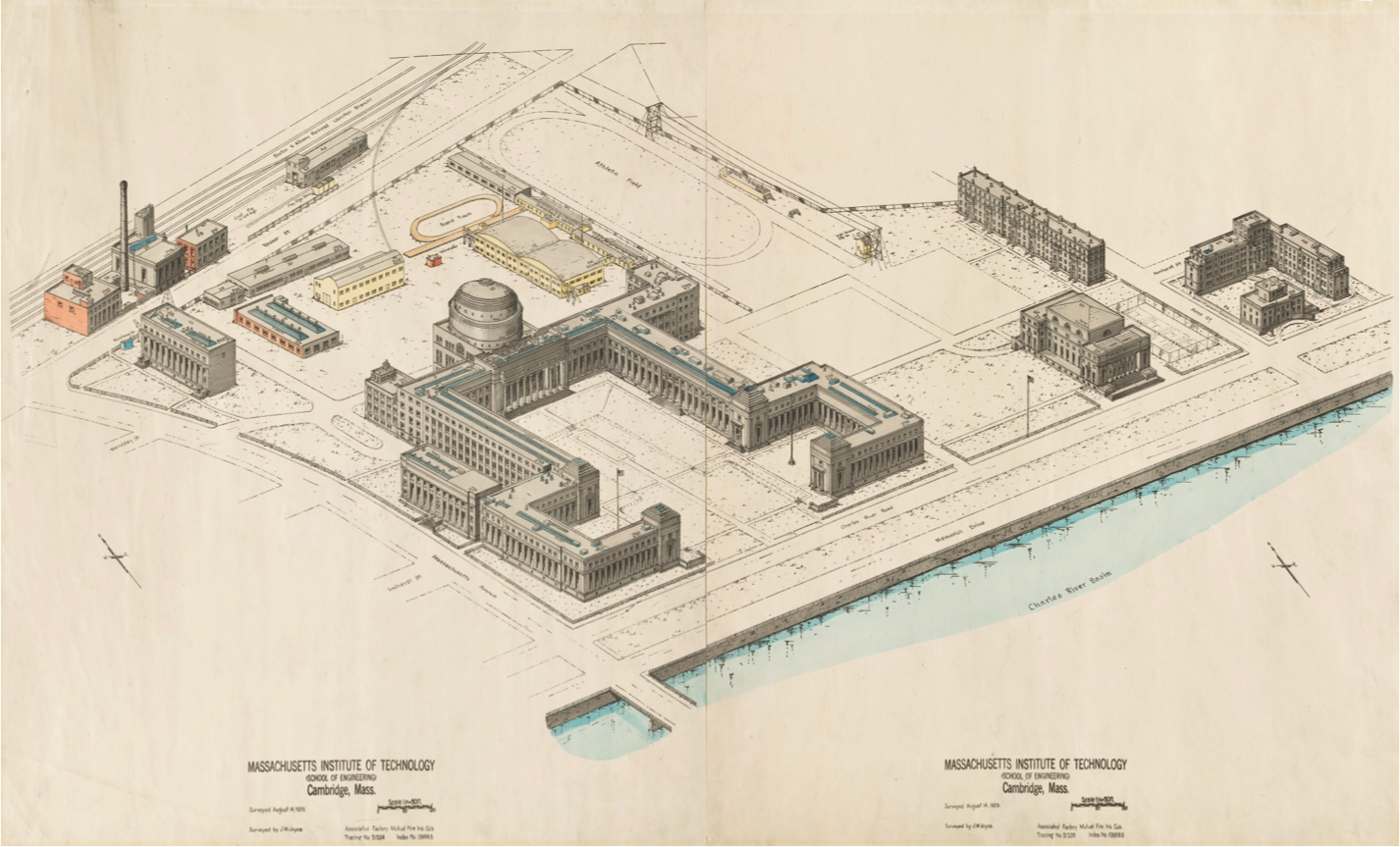

From the beginning, MIT has pursued on-campus power generation—and has pursued greater efficiency and innovation at the same time.

The first Central Utilities Plant (CUP) was a coal-fired district steam and electrical power plant, a state-of-the-art setup for 1916. Steam produced by its four boilers provided heat for the Main Group buildings in winter and also powered generators that produced electricity for Main Group elevators, supply and exhaust fans, and lights. This central facility was a far more efficient option than installing a coal furnace in every building on campus. MIT boosted the plant’s efficiency by locating it next to the Grand Junction Railway to streamline the transfer of coal from rail cars into storage.

As energy options and equipment evolved, so did the CUP. In 1933, the plant’s four boilers were converted from coal to No. 6 fuel oil—a cleaner primary fuel. And in 1950, technological advances enabled MIT to replace the boilers with two new ones that had 2.5 times the steam-generating capacity as the original four. Another advantage of the new boilers was that they could run on natural gas—again, a cleaner fuel—as well as No. 6 oil.

When building the campus, MIT included a state-of-the-art district steam and electrical power plant. This drawing of the Cambridge campus from 1929 shows MIT's Central Utilities Plant in the upper left corner, located along the railroad tracks.

Image courtesy of the MIT Department of Facilities

More changes at the CUP in ensuing decades included the expansion of fuel storage capacity, the addition of a chiller plant and cooling towers, and multiple equipment upgrades. MIT also began transitioning to a higher-grade, more refined fuel: ultra-low-sulfur diesel (No. 2 oil). And in the late 1980s, as the public utility grid grew increasingly expensive and unreliable, the Institute (which had stopped producing electricity at the CUP in 1938) began to investigate a return to on-campus electricity production. A decision was made to develop a solution based on cogeneration, a system which would provide both heat and electricity.

The CUP’s William R. Dickson Cogeneration Facility at MIT began operating in 1995. Due to the unique efficiencies of the process, where one fuel generates both thermal and electric energy, MIT substantially reduced its fuel consumption and greenhouse gas emissions. In the 20 years that followed, MIT avoided an average of 68,000 metric tons of carbon dioxide emissions each year compared to conventional energy sources. During those 20 years, MIT also launched the MIT Energy Initiative (MITEI), the “Greening MIT” campaign, the Office of Sustainability, and a unique collaboration with NSTAR (now Eversource Energy) that reduces energy use on campus.

This year, the Institute is pursuing innovation with a proposed upgrade of its cogeneration facility. The upgrade would replace aging equipment and convert the plant to run entirely on natural gas, except in emergencies and during testing, eliminating the use of fuel oil for normal operations by 2020.

Modeling shows that an upgraded plant will reduce pollutants and lower greenhouse gas emissions, making the cogeneration facility an essential component of MIT’s pledge to reduce greenhouse gas emissions at least 32% by 2030. As an adaptable system, the upgraded facility—flexible enough to incorporate emerging energy technologies and innovations—would also serve as MIT’s bridge to a low-carbon energy future.

Back to Chapter 1 - The Vision: Maclaurin, Freeman, and Bosworth

Learn more

MIT Central Utilities Plant, current day

Image courtesy of the MIT Department of Facilities